Supply Chain Efficiency

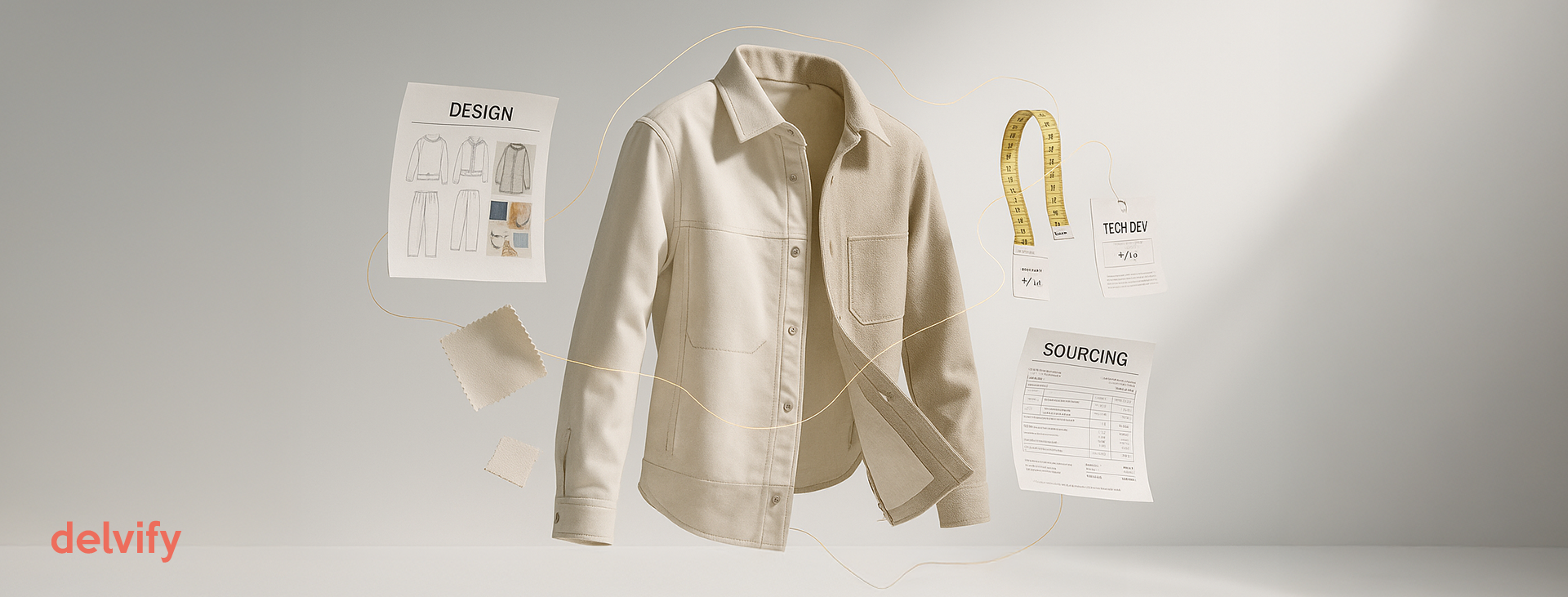

From Trend to Thread: How Design, Tech, and Supply Chain Can Finally Align

TL;DR: From Trend to Thread — How Design, Tech, and Supply Chain Can Finally Align

Sample delays aren’t just a sourcing issue — they’re a symptom of disconnect. When design, tech dev, and sourcing work in silos, suppliers face repeated requests, spec mismatches, and missed opportunities. This article shows how shared platforms like Delvify help manufacturers stay in sync with all brand-side functions — cutting rework, speeding approvals, and driving cross-functional efficiency from the first request.

As a Tier 1 or 2 manufacturer, you don’t just produce garments — you juggle priorities across design, tech dev, and sourcing.

Each team moves at a different speed. Each team uses different tools. And none of them sees what you see.

That disconnect creates chaos long before a sample hits the line.

- A designer specs something sourcing can’t support.

- Tech dev flags a tolerance issue late in the game.

- And you remake a swatch — again — because no one knew it was already in review.

The underlying problem? Brands lack a centralized way to align their teams before involving you. And that blind spot becomes your cost center.

1. Design Moves First — But Tech Dev Sees It Late

Designers often submit moodboards, CADs, or loosely spec’d materials. But by the time tech dev refines specs, it’s too late — you’ve already sampled based on the first request.

Why it matters:

You’re sampling to two versions of the same story — and neither team knows it.

Delvify fix:

Live sample boards, version control, and spec annotations mean everyone — across functions and regions — works from the same starting point.

2. Sourcing Flags an Issue — After You’ve Sampled

You’ve cut the fabric, logged the certs, submitted the sample. Then sourcing replies: “MOQ too high, please suggest another.” No one saw it coming.

Why it matters:

Late-stage pivots mean wasted materials, lost time, and reduced trust — and manufacturers eat the cost.

Delvify fix:

The platform surfaces MOQs, lead times, and compliance tags up front — so changes happen before sampling, not after.

3. You Get Three Separate Requests — For the Same Style

Design asks for a colorway. Tech dev wants composition data. Sourcing wants price. Different teams, same style — and no coordination between them.

Why it matters:

Without unified oversight, manufacturers become the middlemen of misalignment.

Delvify fix:

You get a full, cross-functional view of each request — with status updates and context across design, tech, and sourcing.

4. You Don’t Get Feedback — You Get Another Request

You ship the sample. No update. A month later, a slightly modified request comes in — and you start over, again, with zero insight into why.

Why it matters:

You can’t improve hit rate or suggest smarter options without understanding what landed.

Delvify fix:

All samples and material activity are tracked — so manufacturers see what’s in review, what’s approved, and what needs refinement.

5. Everyone Is Deciding — But No One’s Deciding Together

Design finalizes one fabric. Sourcing overrides it. Tech dev adjusts specs mid-cycle. It’s not malice — it’s misalignment.

Why it matters:

You’re operating on moving targets. That’s where sample waste and missed timelines begin.

Delvify fix:

Delvify connects all decision-makers on one platform — with role-tuned views, shared sample histories, and centralized approvals.

Ready to Align With Every Brand Team — From Day One?

Delvify helps manufacturers eliminate sample inefficiency by plugging directly into brand-side collaboration — across all functions.

- 35% faster time to market

- 60% more reuse of existing materials

- One platform for all requests, briefs, and specs

- Less sample waste, fewer revisions

Book your 20-minute demo at delvify.ai

Frequently Asked Questions

Why do sample delays happen even with good vendors?

Because brand-side design, sourcing, and tech dev work in silos — and vendors are left stitching the gaps.

How can manufacturers align with all brand teams?

Use a shared platform that shows the full request context — including specs, feedback, and decision status across departments.

What if I already use a PLM or vendor portal?

Delvify complements those tools by giving you real-time visibility into how materials and samples move across brand functions — with no manual follow-up.

How does this improve hit rates?

By syncing requests, surfacing red flags early, and reducing unnecessary revisions — so your team samples once, not three times.

What makes Delvify different?

It’s purpose-built for the apparel workflow — with real-time inventory, AI tagging, version control, and vendor-facing visibility all in one role-tuned platform.